Fibre To Fabric: Class 6 Science NCERT Chapter 3

Key Features of NCERT Material for Class 6 Science Chapter 3 – Fiber to Fabric

In the previous chapter: components of food, you studied what are the constituents of food and their significance in painting hood health. You also got to know about diseases caused due to lack of these constituents. In chapter 3 of NCERT class 6 science: Fibre To Fabric, you will study what are fibres and the process of making fabric out of them.

Quick revision notes

Fibres:

All clothes materials are comprised of long, tight, dainty structures called fibres. Fibres are acquired from man-made sources.

Natural Sources:

Cotton, jute, silk, wool, and so forth., are gotten from natural sources-plants or creatures like animals and worms.

Man-made Sources:

Polyester, nylon, rayon and so forth., are man-made materials utilized for making garments.

Plant fibres:

All the plants have fibres in their body structure/parts, e.g., cotton and mango have strands on their seed, coconut on its organic product, jute in its stem and a banana tree in its leaf.

Animals fibres:

Important animals fibres are wool (obtained from the hair of sheep) and silk (obtained from the from a silkworm). Although, Cotton is the most significant industrial crop. India was the proud designer of cotton garments. since 1800 B.C India has been utilizing cotton.

Production: Maharashtra, Gujarat, Punjab, Rajasthan, Tamil Nadu and Madhya Pradesh are the states where cotton is grown.

Atmosphere required: Cotton plants need warm atmosphere.

Cotton is grown in early spring.

Black soil is perfect for cotton’s development.

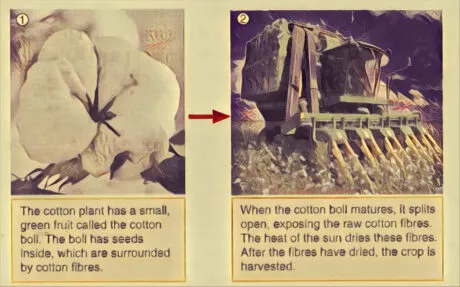

Cotton bolls: Fruits of the cotton plant are round moulded structures of the size of wall nut which are called cotton bolls. On development, cotton bolls burst open, uncovering the white fibres. ‘ At the point when filaments dry in the daylight, they become fluffy.

Cotton fibres: Cotton fibres are gotten from cotton bolls.

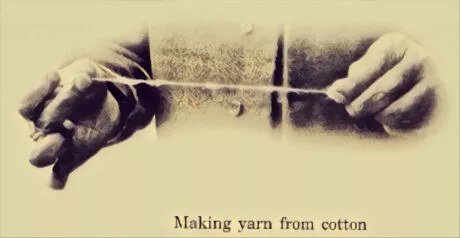

Ginning: The procedure wherein seeds from cotton are pulled out by steel brushes/comb is called ginning.

Charkha: Charkha is a machine on which yarn was spun legitimately from ginned cotton in ancient days.

Bales: Ginned cotton is compacted firmly into packs/bundles weighing roughly 200 kg called bundles.

Silver: Raw cotton from bales is cleaned, brushed and fixed lastly changed over into rope-like strands called silver. A bit of cotton is a free strand or rope of cotton filaments.

Yarn: Sliver is pulled and twisted with the goal that the fibre shapes a solid string or yarn.

Twisting of fibres into yarn expands/increase the union and quality of fibres. Handlooms and power loom: In rural areas, the garments from cotton are woven not on a big scale known as handlooms. On large scale, cotton garments are made by machines known as power looms.

Usage of cotton:

- textiles are manufactured by cotton.

- It is used in a medical clinic as an absorbent.

- fillers in mattresses, pillows and blankets are made up of cotton

- as a principle raw material for the manufacturing of rayon and paper industry.

- Garments from cotton are broadly utilized as mops in the family for household chores and for cleaning machines in enterprises.

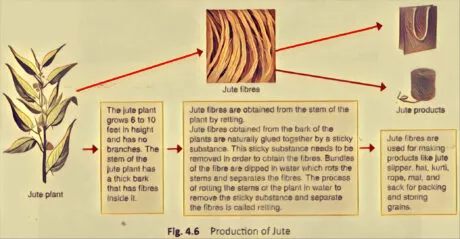

Jute is the most broadly utilized fibre close to cotton.

It is acquired from the stem of a plant called ‘putson’.

In India, jute is basically developed in West Bengal, Bihar and Assam.

Extraction of filaments:

- Jute plants are cut at the hour of blooming stage.

- The cut plants are assembled at various places in the fields for some days when the greater part of the leaves evaporate and fall down.

- Plants are integrated/tied into small bundles.

- Retting: The groups are made to settle down in stagnant water of the lake for some days when the sticky skin spoils out to isolate fibres. The procedure is called ‘retting’.

- Fibre is extricated from retted jute by hand, with jerks and pulls.

Utilization of jute:

- Jute is broadly utilized for making gunny packs, potato sacks, floor coverings, draperies, coarse garments, ropes, and so forth.

- Nowadays, the fine nature of jute is additionally utilized for making jute textures. Ancient people had no clue about garments.

Life of old days people was limited generally to the tropics where the atmosphere was warm and no garments were required. People moved to colder locales simply after the creation of fire. During the stone age, individuals wore bark, enormous leaves or skins of animals. Individuals began wearing sewed garments after the innovation of needle around 40,000 to 50,000 years prior.

Fabric making was created in three phases:

- The first stage was making garments from plant fibres,

- The second stage started with the utilization of animal fibres, and

- The third stage started with the improvement of man-made or synthetic fibres.

The clothes we wear is affected by the atmosphere, occupation, culture and everyday needs.

Clothes are vital for the given reasons below:

- It shields us from wind and climate.

- Also, it shields us from injury.

- It keeps up the body heat.

Woollen and cotton garments feel harsh and that of rayon, nylon or polyester are smooth to contact. The unpleasantness of cotton and woollen filaments is because of numerous folds and uneven surface in it. Silk, rayon, nylon and polyester are smooth since they have long plain, fine structures.

Garments are made from strings and strings (threads), thusly, are spun from fibres. All fibres are not apt to making clothes. Coconut fibre, for example, is extremely hard and must be utilized for making ropes or as coir in beddings. Delicate and long fibres like cotton, wool, nylon, and so on., are accurate to make yarns. It is encouraged/advised to wear cotton garments while working in the kitchen and close to the fire.

Cotton wool:

The pieces of cotton fibres are called cotton wool. It tends to be utilized as absorbent, filling quilts, cushions, and so on and making yarn.

Fabric:

Yam can be woven or sewn physically or by machines into the texture.

Sewing:

The way of making texture from a solitary yarn is called sewing

Spinning:

The way of making yarn from fibres.

Weaving:

The arrangements made to adjust two yarn sets together to make a fabric is called weaving.

Yarn:

The fibres which are spun are called yarns.

Garments are made of various materials. We get these materials from the two plants and creatures.

Distinguish the materials given underneath as plants or creature item. Compose P for the plant items and A for creature items.

Let us find out about how the account of apparel began, the various materials used to make garments, and how they are made. Answers: Cotton socks, jute rope, silk material, foam shoes.

History Of Clothing:

Around 30,000 years prior, individuals began utilizing animal skins to wear. It is accepted that wool was utilized as right on time as 6000 years prior.

Taming of silkworms for silk happened around 3000 BC in China. In India, cotton came into use around 3000 BC. These textures were not sewed. They were simply folded over the body. Indeed, even today, saree, dhoti, and turban are unstitched bits of material.

Fibre And Fabric:

Most parts of the clothes are made from fibres. Fibres are minor (thin) strands of string, that are woven to make fabric, for instance, cotton fabric, silk fabric, and so forth. The fabric is sewed to make garments. For instance, cotton fabric can be sewed into a cotton gown or a cotton kurta. There are two fundamental procedures of making texture from fibre – weaving and knitting.

Weaving:

Weaving includes making fibre by the two arrangements of yarn. It is finished utilizing a machine called a loom, which can be hand-worked (Fig. 4.1) or power-worked. The example wherein two arrangements of strings are in a bit of woven material is known as a weave (Fig. 4.2).

Knitting:

Knitting includes making fabric by framing a progression of associated circles of yarn by utilizing sewing needles or machines. Sweaters are made using wool by knitting.

Characteristic And Synthetic Fibers: (Different Types of Fibers)

Fibres used to make texture might be normal or manufactured. So, fibres obtained from plants or creatures are called natural fibres Models are cotton, jute, fleece, and silk. Fibres that are made by man from artificial substances are called synthetic fibres. Models are nylon, rayon, polyester, and acrylic. Let us get familiar with plant filaments.

Plant Fibers:

Cotton (Fig. 4.3), jute, coir, silk cotton, hemp, and flax are instances of plant strands. The denim used to make pants is produced using cotton.

Cotton:

The cotton plant is a shrub which is cultivated. It develops well in black soil and a warm atmosphere. It needs moderate precipitation. The fibre of cotton is very delicate that develops around the seeds of the cotton plant. An assortment of material items is produced using cotton. In India, ‘lchadi’, a coarse hand-woven fabric, is produced using cotton.

Jute:

Jute is a fibre gotten from the bark of the jute plant (Fig. 4.6). It very well may be developed in various soil types, running from clayey to sandy soil. Also, it develops best in loamy soil (a blend of sand, residue, and dirt), sandy soil, and clayey soil. It develops well in areas where it rains a ton. Practically 80% of the world’s excellent jute originates from Bangladesh. Bangladesh, India, China, Nepal, and Thailand are the primary makers of jute.

Other Useful Plant Fibers:

There are other significant plant fibres also.

Coir:

Coir is the fibre acquired from the external covering or the husk of the coconut. Typically coconuts are left in water for a couple of months. The husk is then isolated from the nut and beaten with wooden hammers to get the fibre. The fibre obtained in this manner is spun and coloured and is prepared for weaving. Coir is utilized to make a few family unit items like rope and floor covering and furthermore as a stuffing in sleeping pads and pads.

Silk cotton:

Silk cotton is another plant fibre that is usually utilized as a stuffing in the cushion, camping bed, and life coat. This fibre is acquired from the silk-cotton tree, additionally called kapok.

The products of the kapok tree contain fibres that are light and soft (like cotton). At the point when the natural product ages, it blasts open, discharging the strands.

Hemp:

Hemp strands are gotten from the stem of the hemp plant. Its filaments are utilized in the creation of ropes, floor coverings, nets, garments, and paper.

Flax Fibers got from the stem of the flax plant are woven to make linen.